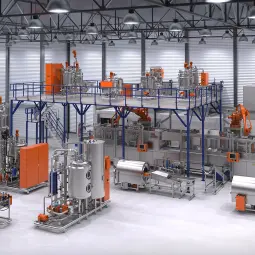

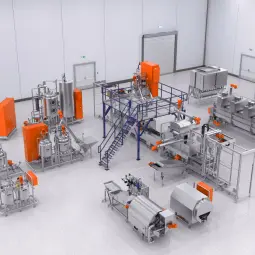

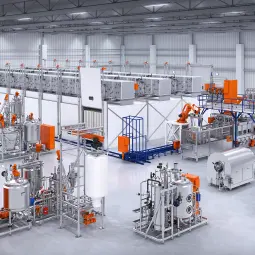

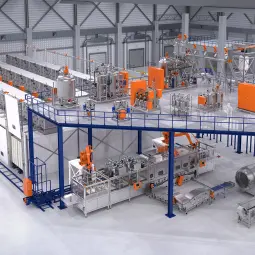

Whether you're crafting traditional confectionery gummies or innovating with new formulations, our advanced systems—featuring cutting-edge automation and gantry robot technology—help you scale production without compromising on quality. With Tanis, you get more than just machinery; you get a complete, future-ready solution tailored to your needs.