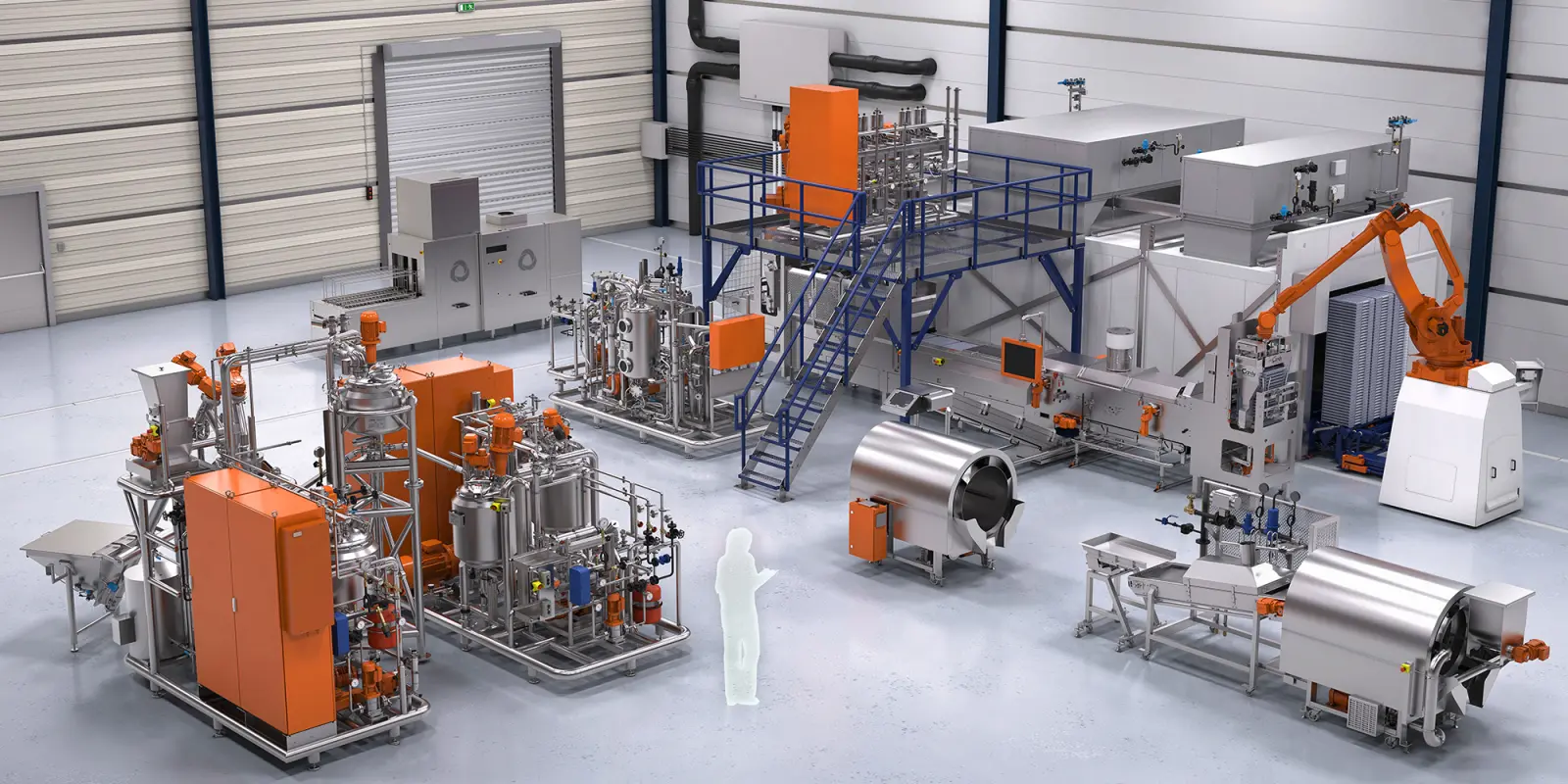

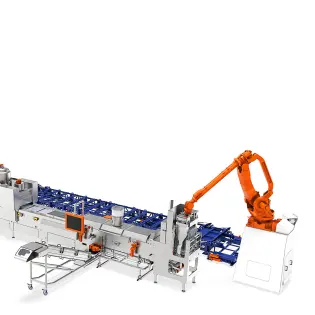

Moulding

The accurate depositing pump and the well thought-out demoulding process guarantee that your yield looks exactly the way it should. Unique is our use of plastic moulds, which are much easier to clean and thereby eliminate any product contamination. We have developed these superior moulds in-house and were the first to use them at substantial capacity, which is something we are proud of!