Premix preparation

Suitable for any type of gelling agent. Has a cone-shaped weighing and mixing vessel which eliminates the need for a pre-gelatin dissolving unit.

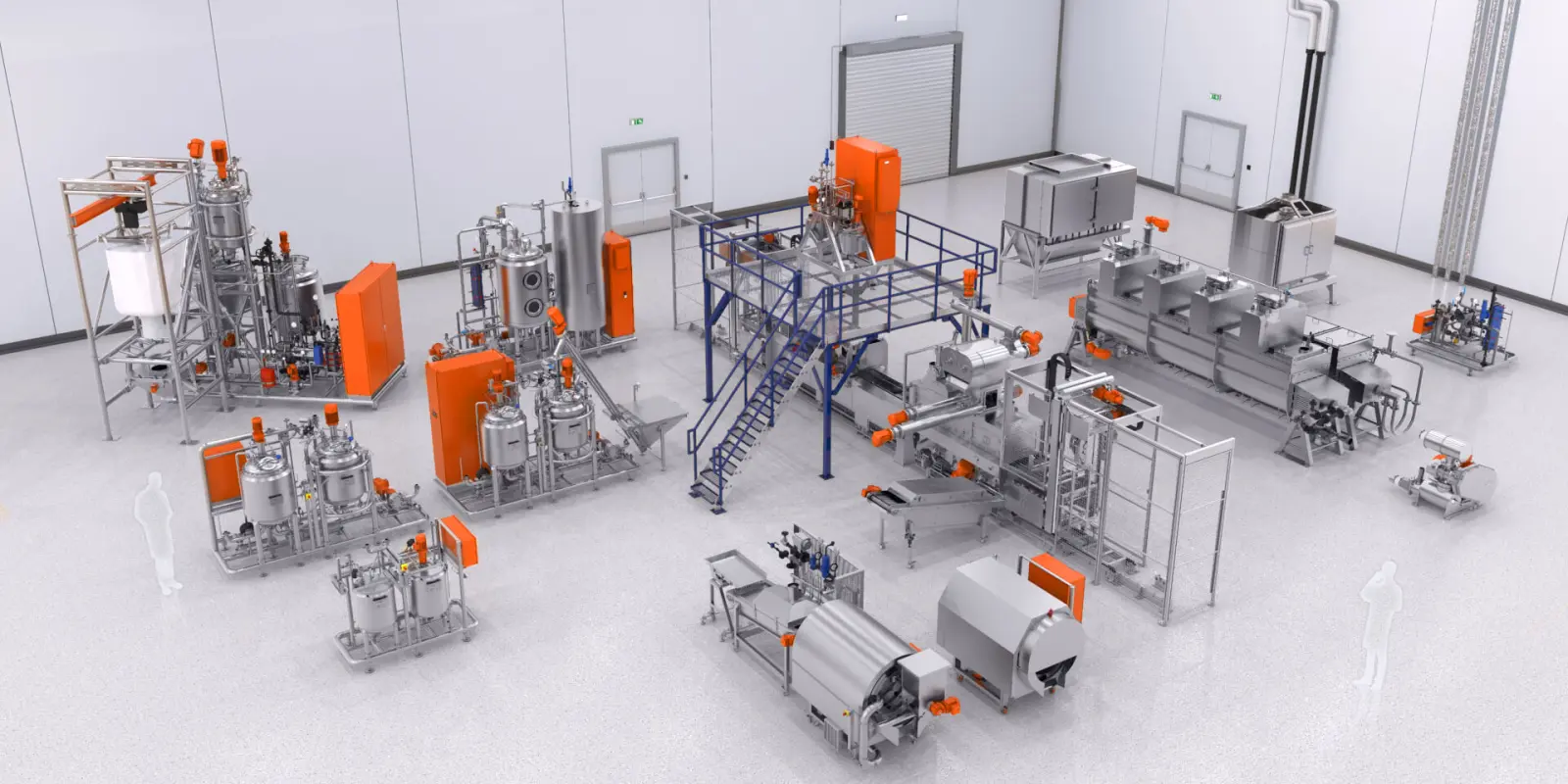

The Tanis 400 Compact is a fully-integrated automatic production line which combines a compact footprint with impressive versatility and capacity per square metre / foot. Recipe driven, with a kitchen that can be configured in various ways, plus fast changeover between different recipes, it’s ideal for those with limited space who want to produce a wide range of gummies, jellies and nutraceuticals.

Suitable for any type of gelling agent. Has a cone-shaped weighing and mixing vessel which eliminates the need for a pre-gelatin dissolving unit.

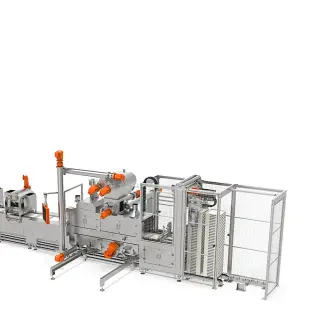

Automatic Moulding line ensures trouble-free demoulding, starch filling and printing, thanks to the state-of-the-art T-Gel Depositing Pump. This skid is also suitable for replacing traditional machines in existing lines.

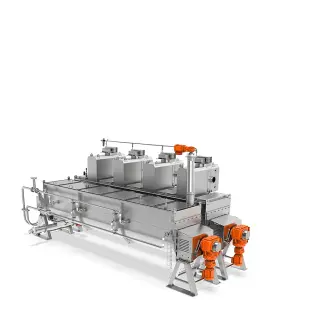

Ensures the starch has the right moisture content. This adds to process safety and creates optimal printing results.