Acid

Acid plays a crucial role in determining the shape and texture of the finished product. This skid can easily be expanded to enable production with more than one acid, opening up new opportunities.

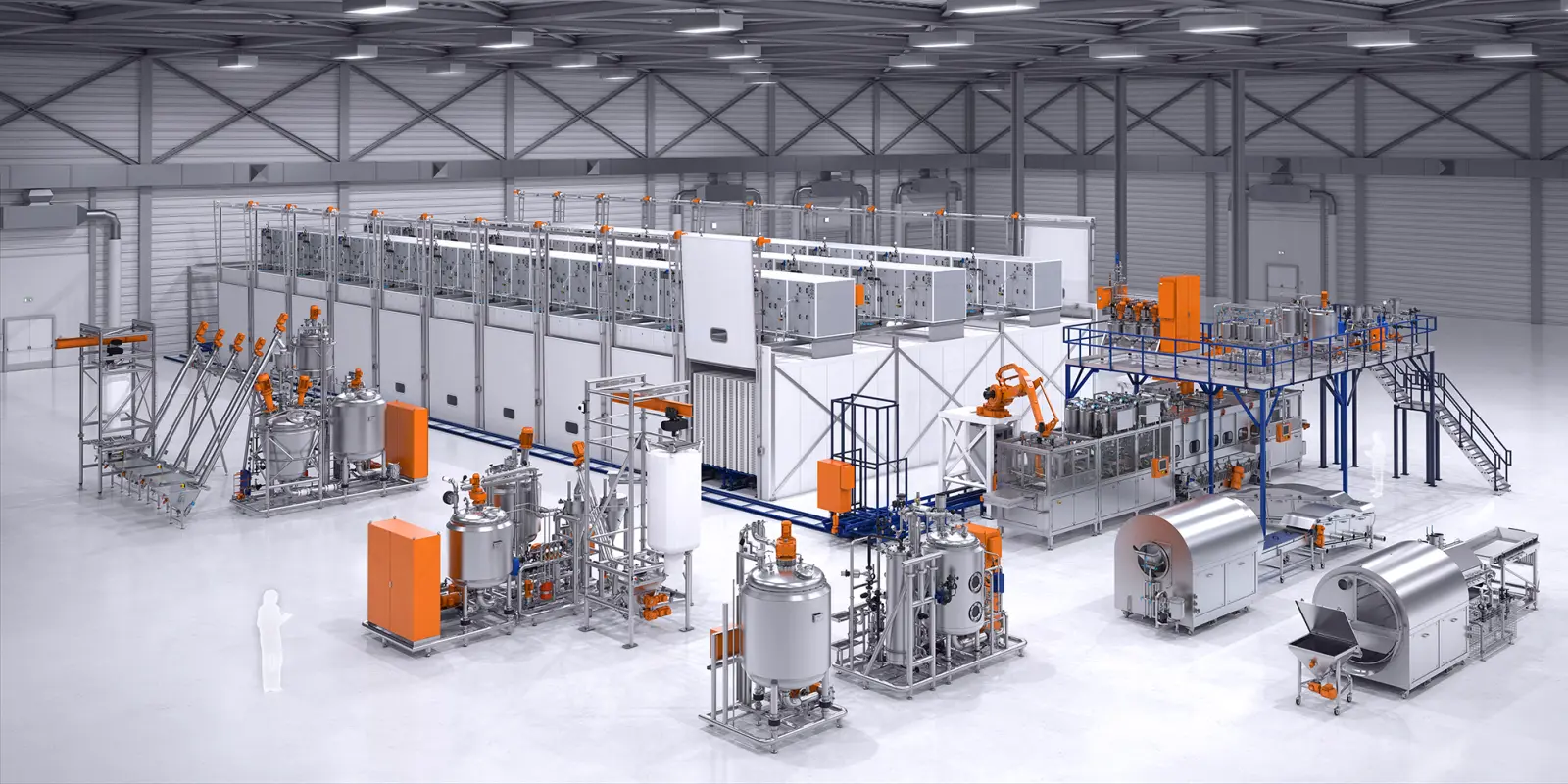

Featuring double tray movement which enables high capacity from low machine speeds, the Tanis 800 Robotic High Capacity is a versatile solution for manufacturing gummies, jellies and nutraceuticals. This recipe driven, fully-integrated automatic production line with Automated Track System (ATS) automatically adjusts for optimal, synchronized operation. Kitchen configuration options make the best use of available space and the line requires just three operators.

Acid plays a crucial role in determining the shape and texture of the finished product. This skid can easily be expanded to enable production with more than one acid, opening up new opportunities.

Servo driven double tray transportation effectively doubles capacity without increasing internal machine speed. This allows more time for starch filling and depositing, which facilitates higher accuracy. Combined with the functionality of the eye-catching robots which handle the trays, this skid guarantees repeatedly consistent yield.

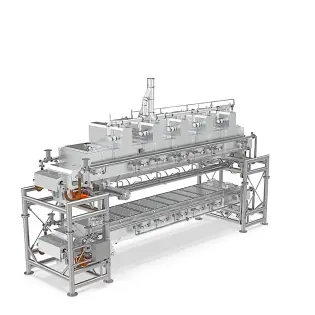

This cooler-dryer conditioning skid ensures the starch has the right moisture content. This adds to process safety and creates optimal printing results. These units have been designed with carbon footprint reduction in mind, by enabling low energy consumption.