Types of candy molds for caramel making

Determining the shape of your caramel confectionery product is crucial. A bar line process can produce caramel bars or squares, while a depositor allows for more intricate shapes, such as round domes. These dome-shaped caramels can also serve as centers for chocolate-coated dragees.

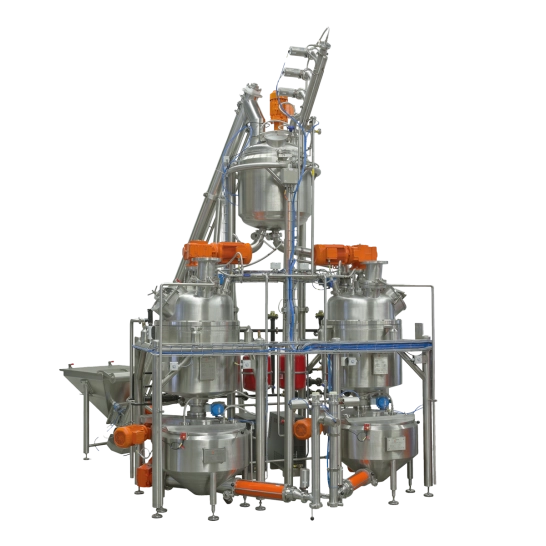

Molds are essential for shaping and portioning caramel into specific sizes and shapes. Depositors accurately place the right amount of caramel into molds. These molds are available in various materials, including polycarbonate, Teflon-coated metal, or silicone, each chosen for its durability and temperature resistance to handle hot caramel.

Precise monitoring of temperature and dry solid content is vital when depositing caramel into molds. For caramels that are formed rather than deposited, the dry solid content is typically higher to facilitate shaping.

In addition to molded caramels, caramel is frequently incorporated into layered confectionery products, such as candy bars. In these applications, a slab of caramel is layered over a base, such as a cookie or nougat. This caramel is still prepared using the described equipment, but once ready, it is processed on a bar line where the slab is formed. The final characteristics of the caramel can be varied by adjusting the ingredients; for example fat content, the duration of the caramelization process and dry solid contents, which allows for the customization of the caramel's texture and flavor according to specific product requirements.

How to use a candy thermometer for caramel making?

Temperature control is critical in confectionery production. The duration that caramel ingredients are held at a specific temperature influences the development of the caramel's brownish color and its flavor notes. Keeping the caramel at a slightly higher temperature for 15 minutes could result in a dramatically different flavor profile. Similarly, cooking the mixture just 1 degree higher can increase the dry solid content, resulting in a firmer texture. Therefore, precise temperature measurement is crucial in the caramel-making process.

The temperature probe should be immersed in the caramel mass to provide a constant and accurate reading. Typically, this probe also acts as a control point for the heating source—whether steam or electric induction—to ensure the caramel consistently follows the same time-temperature profile. This consistency is key to achieving uniform flavor, color, and texture in the caramel.

Using a candy thermometer correctly involves more than just monitoring the temperature; it’s about actively managing the heat source based on the readings. Here are a few additional tips:

Calibration: Before using the thermometer, ensure it is calibrated. You can do this by placing it in boiling water and checking that it reads 212°F (100°C). Adjust if necessary.

Placement: Place the thermometer so that the tip is in the deepest part of the caramel without touching your heat source. This helps in getting the most accurate reading.

Reading and Adjusting: Constantly monitor the thermometer during cooking and adjust the heat source accordingly. This allows for fine control over the cooking process and helps prevent burning or undercooking the caramel.

By following these practices, you can ensure your caramel achieves the desired texture and flavor characteristics consistently.

Precise temperature control is essential when making caramel, and a candy thermometer can help achieve this, resulting in delicious, consistent caramel. Temperature and cooking time significantly affect the final color, flavor, and texture of caramel.