Why is good equipment necessary?

Caramel-making equipment is essential for achieving the precise temperature control and mixing required to develop the rich flavors and textures characteristic of high-quality caramel.

Processing caramel means mixing the ingredients to an emulsion and heating it such that its colour and flavour develop optimally. The possibilities for the application of caramel are endless.

Caramel-making equipment is essential for achieving the precise temperature control and mixing required to develop the rich flavors and textures characteristic of high-quality caramel.

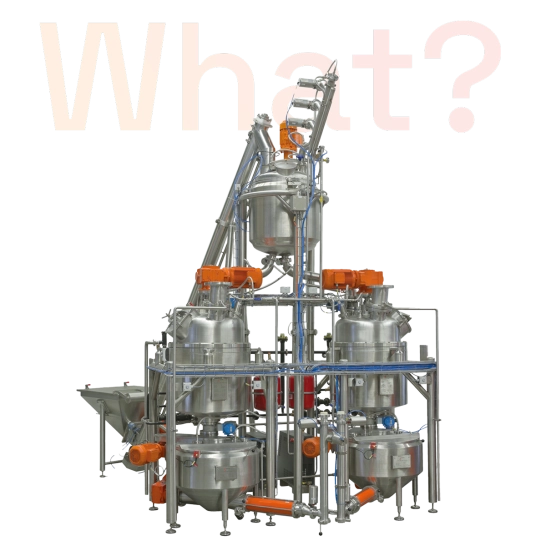

The key equipment includes a premix preparation vessel, fat melter, Maillard reactor, film cooker, and dynamic mixer. These tools ensure consistent results by managing each step, from ingredient blending to achieving the ideal caramelization.

The process starts with mixing and melting ingredients, followed by controlled heating in a Maillard reactor and film cooker, ensuring the perfect caramel texture and flavor.

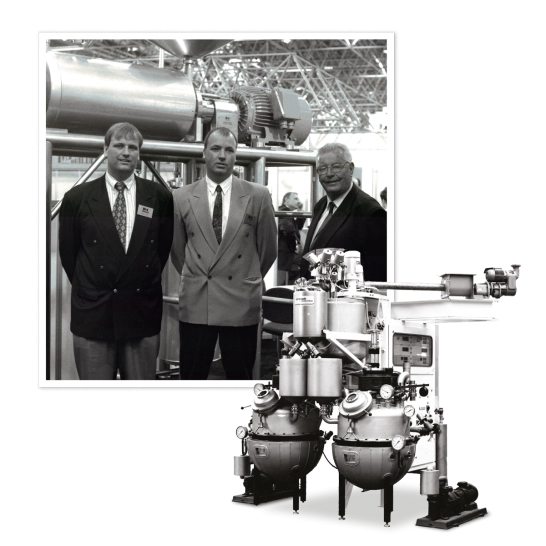

At Tanis, we take pride in our deep-rooted legacy in kitchen equipment craftsmanship. This expertise dates back to Nees Tanis, father of our founder Leo Tanis, who earned global recognition as the Owner and CEO of Ter Braak, a renowned kitchen supplier established in 1946. This rich heritage of knowledge and dedication has been passed down through generations, enabling us to consistently deliver top-quality kitchen skids to our worldwide clientele.

Would you like to discover all the benefits of working with the global leader in confectionery production equipment? From lifetime support to passionate guidance from our experts? Get in touch with one of our specialists or request our brochure.