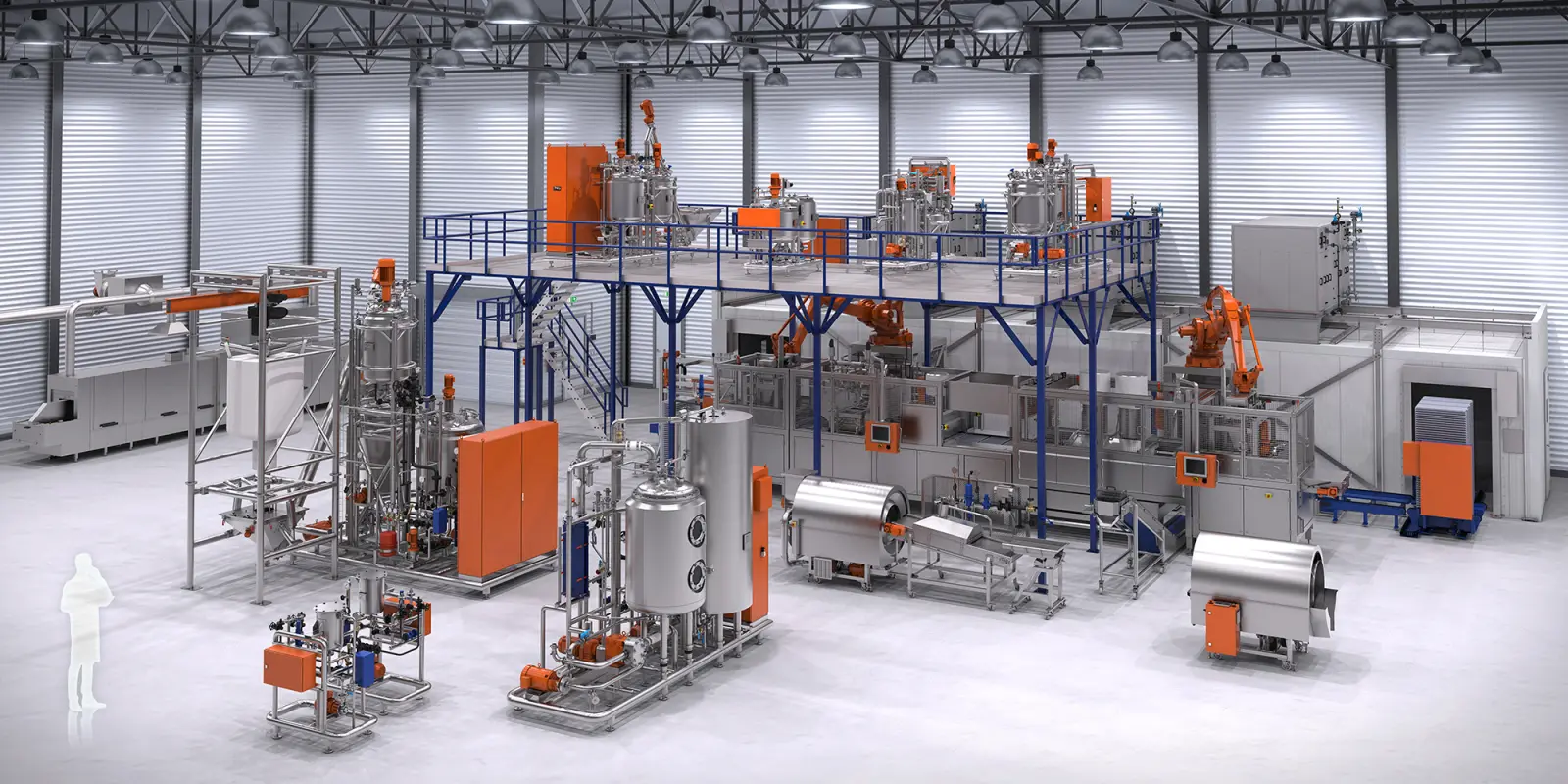

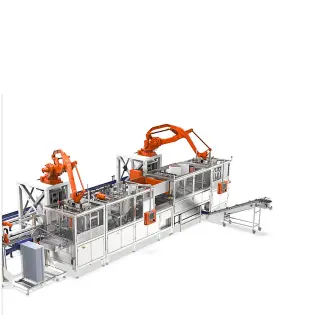

Cooking

This skid ensures a continuous cooking process, without unnecessary interruptions. The large vacuum vessel increases efficiency by reducing movement in the candy mass, thereby preventing air bubbles forming within. Various types of cookers can be installed on this skid as required.