ABS

The Additive Blending System is where the sugar mass is enriched with color, flavoring, acid and optional functional ingredients. This Single Deck ABS (SDA) skid ensures accurate dosage.

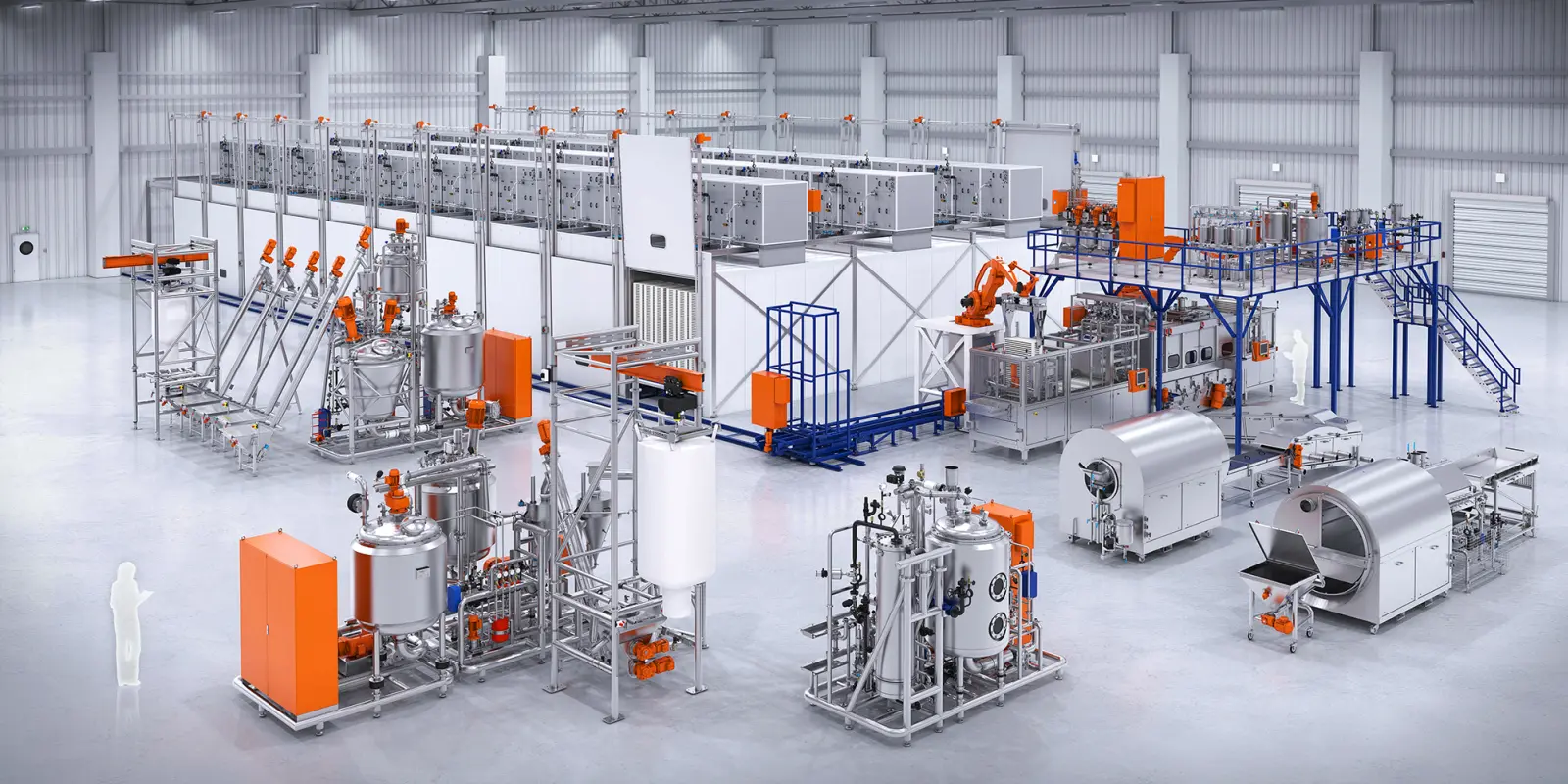

This fully-integrated automatic production line with Automated Track System (ATS) is a highly versatile solution for manufacturing gummies, jellies and nutraceuticals. Requiring just three operators, the Tanis 800 Robotic is recipe driven and its components automatically adjust as necessary for optimal, synchronized operation. Various kitchen configuration options enable it to fit available space.

The Additive Blending System is where the sugar mass is enriched with color, flavoring, acid and optional functional ingredients. This Single Deck ABS (SDA) skid ensures accurate dosage.

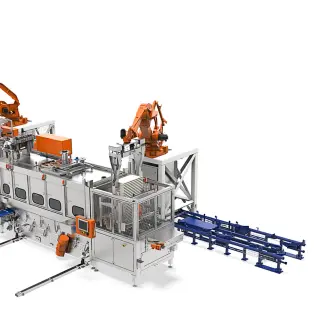

Servo driven single tray transportation and positioning ensures trouble-free demoulding, starch filling and printing. This, combined with the functionality of the eye-catching robots which handle the trays, guarantees repeatedly consistent yield.

Specifically designed to polish your gummies and jellies to perfection, while also ensuring they don’t stick together.