What equipment is needed to make gummy bears?

The delightful world of gummy bears is not just about the sugary goodness that melts in your mouth; it's an complicated combination of equipment and processes that bring these iconic treats to life. Let's take a behind-the-scenes look at the specialized manufacturing equipment involved in the art of making gummy bears.

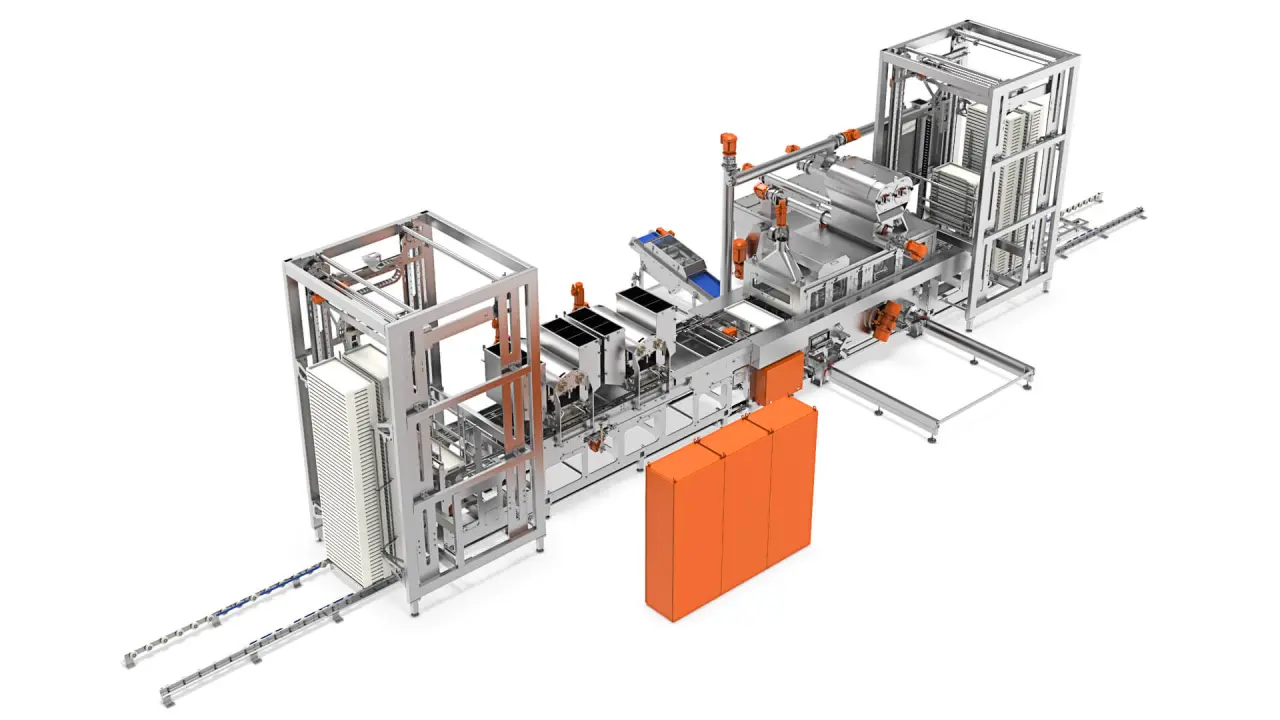

Gummies and jellies are manufactured through a carefully controlled sequence of four stages, each supported by specialised equipment. Production begins in the kitchen, where ingredients are precisely weighed, mixed, cooked under heat and vacuum, and then blended with flavours, colours, acids, and other functional components. Next comes moulding, which may use starch-based or starch-free depositing systems to shape the candy mass into its iconic forms. The third stage is conditioning, during which controlled temperature and humidity ensure proper drying and texture development. Finally, the process concludes with finishing steps such as oiling or sanding, which enhance appearance, mouthfeel, and product stability. Below, we will examine each stage in detail — step by step.