Think gummies

A sweeter pill to swallow

For millions of people every day, swallowing pills and capsules to get their nutritional supplements is a highly unpleasant experience. For millions more, it isn’t even an option. What if vitamins, probiotics, CBD, collagen and other active compounds came in a soft, easy-to-chew substance with an appealing taste? What if they could exist within gummies?

Nutraceutical gummies: a complete solution

You could say gummies are the perfect medium for nutraceuticals.

- Highly accurate dosing

- Easy to combine different types of active ingredients

- Excellent shelf-life stability

- Appealing flavors, unpleasant tastes masked out

- Low sugar and sugar-free options

Gummies can satisfy regulatory requirements for accuracy, efficacy and stability of active ingredients. Unlike pills and capsules, they can contain both wet and dry active ingredients within a single piece. And with the right recipe, bitter tastes present in some active ingredients, such as CBD, can be elegantly masked.

Worried about sugar? Gone are the days when eating a gummy meant consuming an unhealthy amount of sugar. Today’s recipes can be low sugar or completely sugar-free. And still taste delicious.

Making supplement time something to look forward to

Imagine how different the daily routine could be for all the children, elderly and those with conditions which make swallowing pills and capsules something they dread. Or the opportunities to improve health in those who can’t swallow hard supplements at all.

With nutraceutical gummies, they can get their daily health boost or sleep aid in a pleasantly tasting, easily chewable snack.

The market is poised for product

When a product gains traction in the USA, markets across Europe soon follow.

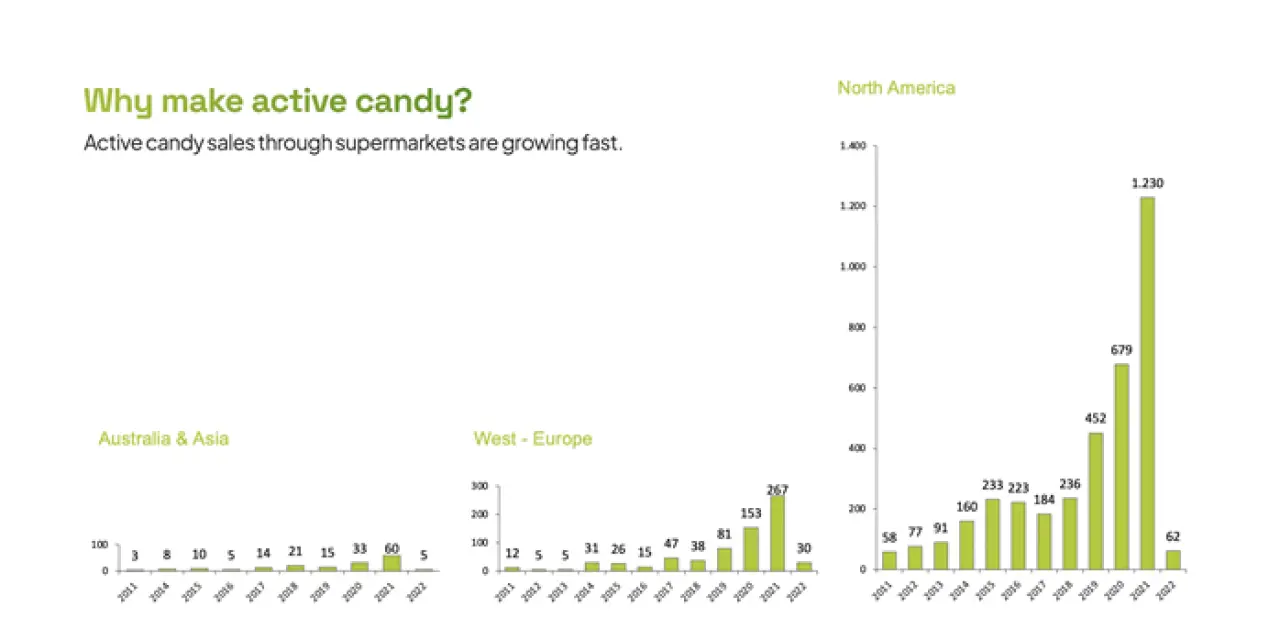

Since nutraceutical gummies started appearing in American supermarkets around 2008, with 21 product introductions, the category has grown exponentially. In 2021, the number of new introductions had risen to 1,230.

Since the first 31 nutraceutical gummy introductions appeared in European supermarkets in 2014, the exact same trend has emerged, with 225 new introductions appearing in 2021.

With Europe six years behind the US, the trajectory can reliably be predicted. Many supermarkets across the continent are already recognizing the opportunity by making more and more shelf space available.

Will you be there to fill that space?

Financially-viable, premium product

Nutraceutical gummies are a unique and necessary product that sustain a notably higher market price than regular confectionery. The USA has demonstrated demand at between $0.20 and $2 (wholesale) per gummy, depending on the active ingredient.

Tanis’s entry-level production line produces 10,000 – 30,000 gummies per hour. At the other end of the scale, our highest-capacity model can produce up to 2.5 million pieces per hour. With our help, and the right distribution channels, the investment needed to participate in this fast-growing market can be returned within 1 year.

Together, we can improve millions of lives

With the right equipment and recipes, making high quality nutraceutical gummies isn’t difficult. But there is, of course, still plenty you’ll want to know before you commit. We’re used to that at Tanis. In fact, we have a webinar course designed specifically to get newcomers up to speed.

Gums and jellies course

We’re also more than happy to work together with you, confidentially, to co-develop your own unique recipes. Recipes that perfectly combine every requirement, from nutraceutical accuracy and stability to appealing taste and texture. We’ll turn you into a nutraceutical gummy master chef in no time!

And, of course, if you purchase Tanis equipment, we’ll continue looking after you through our comprehensive service programs.

Tanis production lines for nutraceutical gummies

Tanis has been making kitchen equipment for various kinds of confectionery since 1995. And the expertise our company is founded on goes back way further. Since 2014, we have specialized in making complete production lines for gummy and jelly sweets.

This focus on gummies and jellies is really important, because it enables us to pay attention to the smallest of details, and how they all interact to influence the final result.

Nutraceutical gummies require a very specific balance that maintains active ingredient efficacy, ensures accurate dosing, masks unpleasant flavors and avoids cross-contamination.

Tanis production lines have been perfected to deliver all of this. We have complete lines suitable for a wide range of capacities, as well as different levels of automation and options for starch and non-starch moulding.

Learn more about Tanis non-starch production lines.

What’s the big deal about starch?

When we talk about starch and non-starch production lines, this has nothing to do with starch content within the gummies. It’s about the use of starch powder in the production process as a flexible base for lining moulding trays, to create your candies’ unique shapes.

This is the traditional method for depositing candy mass a standard technique, and is a popular choice for making functional gummies. However, Tanis has also developed an alternative system which doesn’t use starch and thereby avoids dusty starch powder swirling around your factory, so you have a cleaner environment for making nutraceutical gummies, with a greatly reduced risk of cross-contamination.

Tanis non-starch gummy production lines work with a special type of plastic tray which can easily be hygienically cleaned between recipes. Other aspects within the lines, and the recipes they run, are also adjusted to enable smooth release of produced gummies from the non-starch-lined trays.