Tools for Chewy Candy Making

Kitchen: Batch Cooking

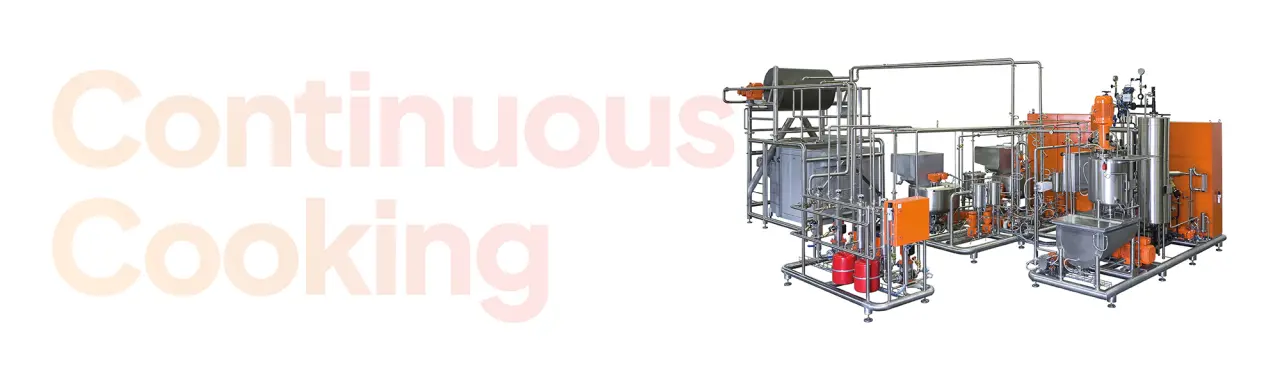

The premix for chewy candy is transferred to the thermosyphon cooker, cooked to the preset temperature followed by vacuumizing before discharging into the aerating vessel. The production process is all about the controlled and quick heating of the solution in order to obtain a clear sugar solution. The special design of the heating coil creates a very rapid and accurate dissolving and cooking cycle.